Ichalkaranji, Kolhapur, Maharashtra

- GST NO. : 27BERPK2695M1ZL

38,000.00 / 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Download | |

| Application | Medical Use |

| Warranty | 1yr |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Automation Grade

Manual

Pack Type

Carton Box

Machine Type

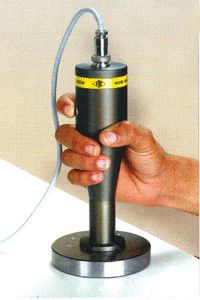

Portable

- It is found that measuring Brinell indentations can result in measurement errors between operators. This B.I.A.S. can virtually eliminate operator influence on test result. - The B.I.A.S virtually eliminates operator influence

- With this handy instrument entire test sequence is simple. Place the scan hand on the work piece on 'Auto' in tool bar on computer screen. The B.I.A.S. automatically measures the diameter of indentation with resolution of 0.01mm and display Brinell value with diameter measurement. All data storage functions are automatically performed according to batch parameters. - Just place and click! Operating B.I.A.S is easy

- An unlimited number of batches can be created each with its own test parameters and certificates. The operator can select test load and indenter size with arty name, address,

- certificate no. date batch no. and description, high and low limits for readings etc. The previous batches can be reopened for viewing and address change etc. - The B.I.A.S. can be configured to meet your needs

- The B.I.A.S. has built in statistical capabilities with graph and certificate for report generation and printing. It includes frequency distribution and variation graphs.

- The systems includes calibration and check facilities to calibrate the systems and for checking of calibration. This eliminates any systems error in measurement.

THE SOFTWARE

- Facility for Auto / semi Auto / Manual modes of operation.

- Well managed database saves readings with respect to batch and certificate.

- Report generation in the form of certificate and graph as per customer requirements.

- Facility for calibration and check of calibration.

Specification:

The range of Measurement is from 1mm to 6 mm of diameter with Resolution of 0.01mm.

Applications:

- To measure Brinell Hardness directly on machine where presently Brinell-Microscope is used. This avoids eye straining of operator on producing testing. In addition, it gives far better repeated accuracy. High-low limits selections enables operator easy acceptance / rejection of components.

- Easy to transport anywhere and handy for use with easy setup.

Looking for "Brinell Image Analysis System" ?

Piece

Explore More Products